MICOM P is the complete package for automated class evaluation of oil purity. Comprising of a microscope with a motorised stage, a matching microscope camera, and the Lambdasoft program to control stage movement and image capturing, the system can be used to quantify particulate contamination levels per millilitre of fluid, according to ISO 4406, CSN 65 6206, NAS 1638, AS 4059 or GOST 17216.

After employing ‘vacuum filtration’ to prepare a sample onto 47 mm filter, the system can automatically identify, measure and classify the particulates according to their dimensions, according to the chosen standard (e.g. ISO 4406). Further image analysis then allows determination of the oil purity class.

Via the PC, the user can select from a range of predefined options to optimise the analysis. The Lambdasoft program also allows advanced control of camera parameters such as brightness, contrast, and exposure; and various image analysis factors, including thresholding, filtration, size determination method. The captured images can be saved into a database, allowing more complex image analysis using non-routine parameters.

The microscope assembly includes the microscope body, trinocular tube, 2 eyepieces {10x}, objectives {4x, 10x, 20x}, colour camera and the objective-micrometer {1mm/100}. The connection between the microscope and computer is via standard USB.

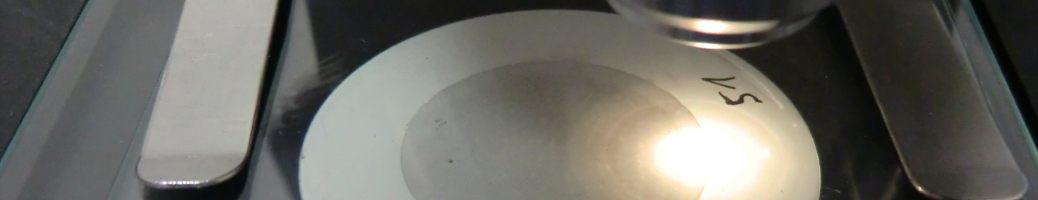

A dedicated objective-micrometer allows easy verification of calibration and accuracy of the optical system. We suggest a ‘calibration assessment’ after replacing any element of the optical system or camera.